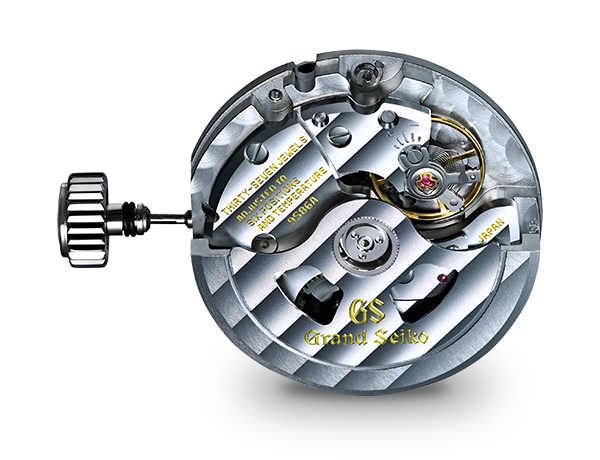

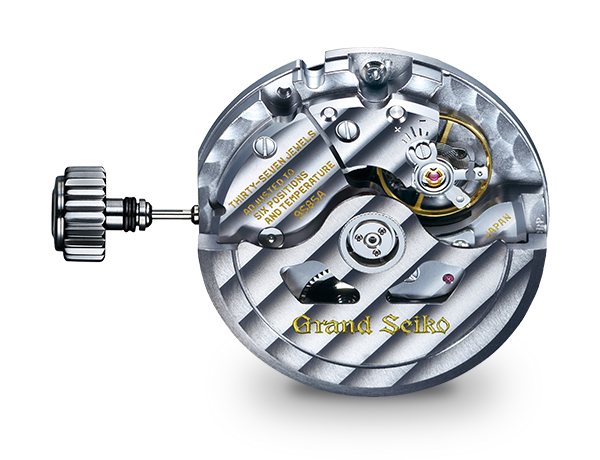

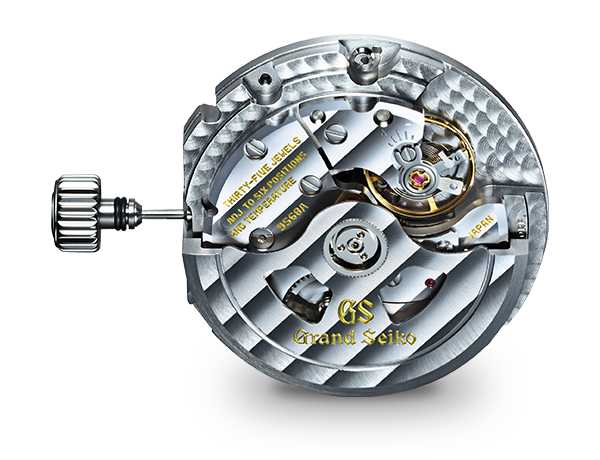

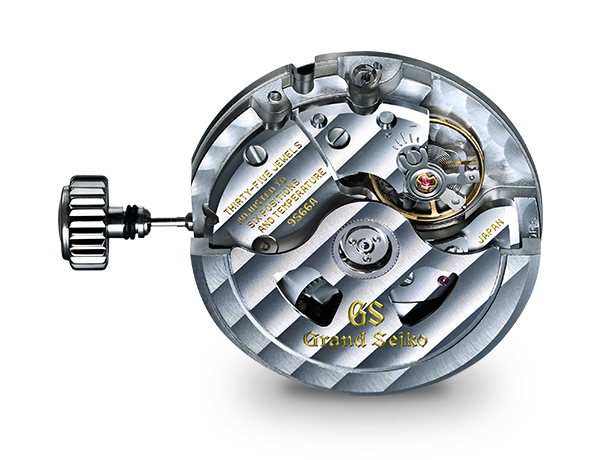

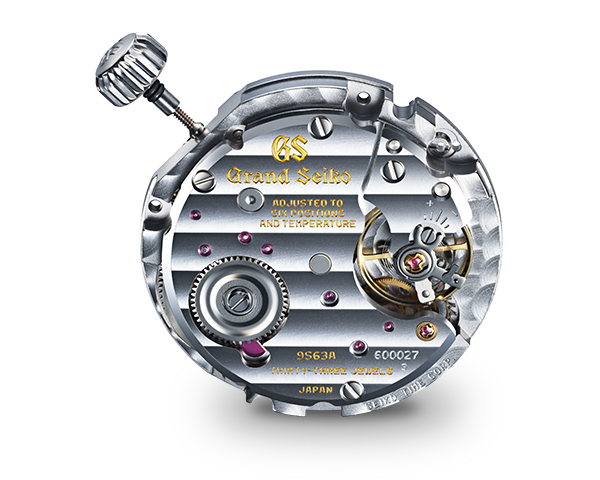

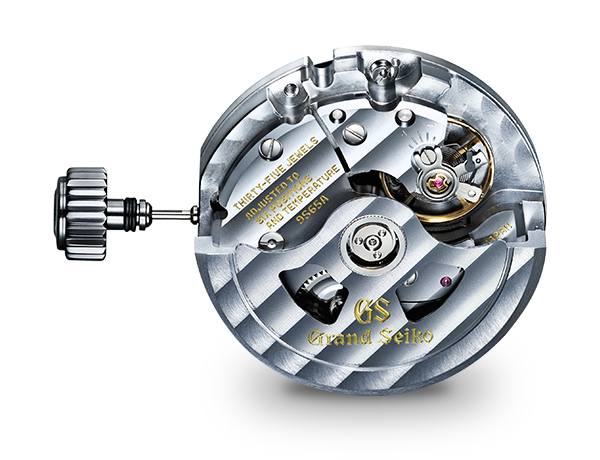

Automatic 3-Day Power Reserve

Caliber 9S65

Caliber 9S65 is automatic movement that typifies the whole 9S mechanical series. It is similar in design to the first generation of 9S calibers but offers enhanced performance.

MEMS (Micro Electro Mechanical System) is a technology first developed for semi-conductor manufacturing. It is used in the production of the escapement of Caliber 9S65 as it allows the creation of components that are lighter, of more complex shapes and more precisely engineered. While the winding system of its predecessor, Caliber 9S55, used Grand Seiko's Magic Lever mechanism, Caliber 9S65 uses a reverser gear train system. Hardening the components allowed greater durability for this reverser.

Specifications

| Winding mechanism | Automatic with manual winding mechanism |

|---|---|

| Mean daily rate*1 | +5 to -3 seconds per day |

| Normal usage accuracy | +10 to -1 seconds per day |

| Power reserve | Approximately 72 hours |

| Vibrations | 28,800 vibrations per hour (8 beats per second) |

| Number of jewels | 35 jewels |

| Features | -Date display |

- Mean daily rate is a mean value of daily rates in a condition where the movement before assembly in a case is measured in six positions in a fixed manner under artificially controlled environment for 12 days.

What makes 9S Mechanical special?

The concept of Grand Seiko was born from the desire to build the world's best watch, and the collection continues to push precision in mechanical watches to the limits of timekeeping technology.

As a true manufacture, Grand Seiko combines the latest technology with hand craftsmanship to raise the art of mechanical watchmaking to the highest possible level.